WRA

ErP

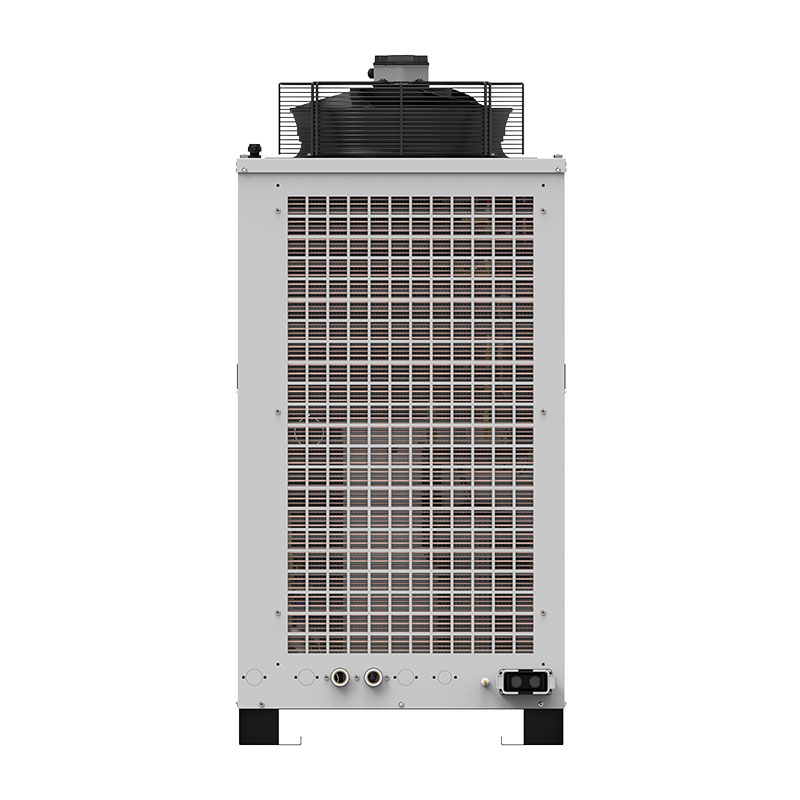

Air-cooled liquid chillers, ErP2021, scroll compressor, R410A, R134A, 5 – 47,5 kW

After thousands of WRA units installed worldwide since 1989, the WRA ErP is the next generation of high efficiency chillers specifically designed for industrial process cooling.

WRA ErP is the result of a design that has focused on reliability, energy efficiency, the extension of operating limits, and extreme configurability.

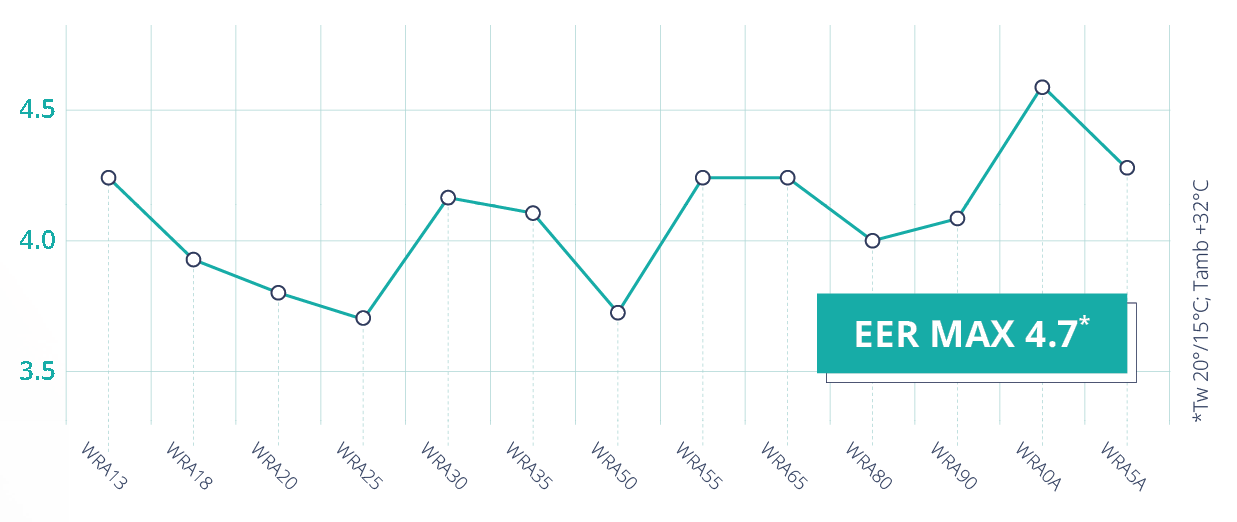

Thanks to dedicated technological solutions such as the enlarged heat exchangers, the standard electronic expansion valve, and the new high-efficiency fans, each configuration of the WRA ErP is characterized by high thermodynamic performance, which exceeds the most stringent minimum energy efficiency requirements imposed by the Ecodesign directive starting from 2021.

High energy efficency

WRA ErP works with high thermal load continuously throughout the year, thus ensuring the highest performance in any operating condition. All WRA liquid coolers comply with the limits required by the ErP2021 regulation – SEPR HT (EU) 2016/2281 – SEPR MT (EU)2015/1095, becoming the best solution for all process applications.

Reliable

Reliable

Designed with precision and crafted with high-quality materials, these systems offer reliable and long-lasting performance, ensuring a consistent operational efficiency to meet the most demanding needs of your industry.

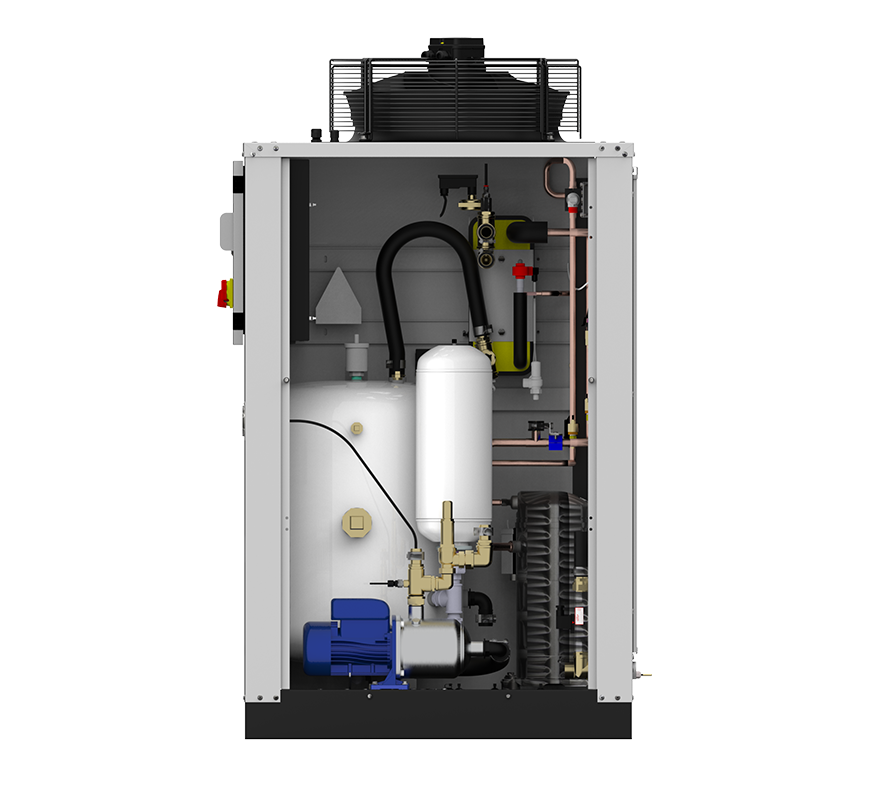

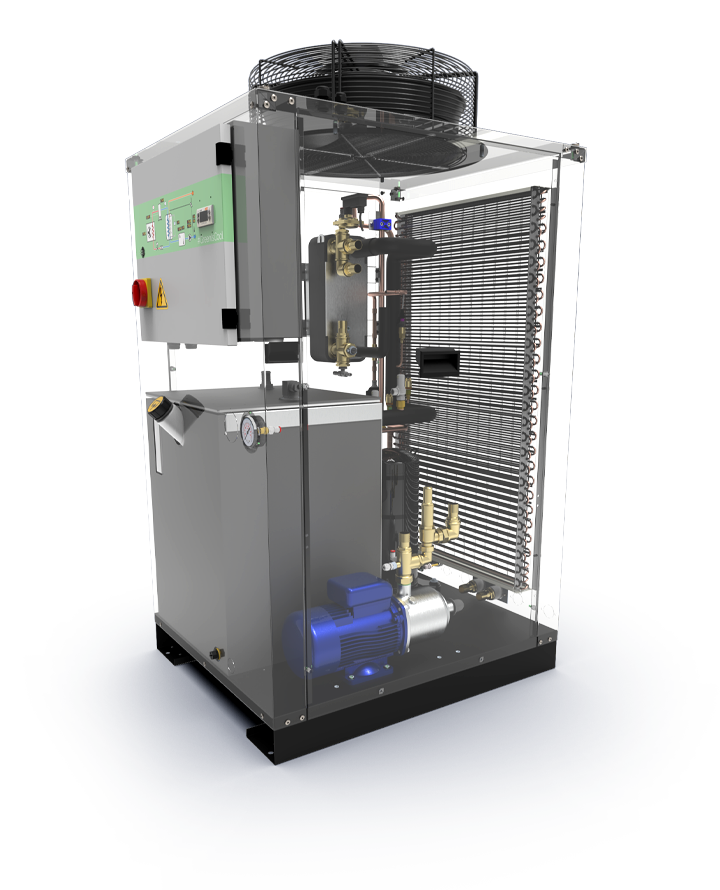

TRIFUGAL PUMPS

High-pressure multistage horizontal centrifugal pumps, specifically designed for process cooling. Available head: P3 – 3barg; P4 – 4.5/5barg; P6 –6/6.5 barg. P5 INVERTER INOX pump with MGE motor equipped with permanent magnets and high-efficiency frequency converter

REFRIGERANT CIRCUIT

Equipped with hermetic scroll type compressors and optimized for operation with R134a refrigerant (mod.13-18) and R410A (mod.20-5A). These high-efficiency compressors are equipped with a 2-pole motor complete with overheating/overcurrent protection and an oil heating resistance. The EEV electronic expansion valve (standard from mod.20) is equipped with sensors placed on the refrigeration circuit and allows to optimize its operation in every thermal load condition, guaranteeing maximum efficiency at all times.

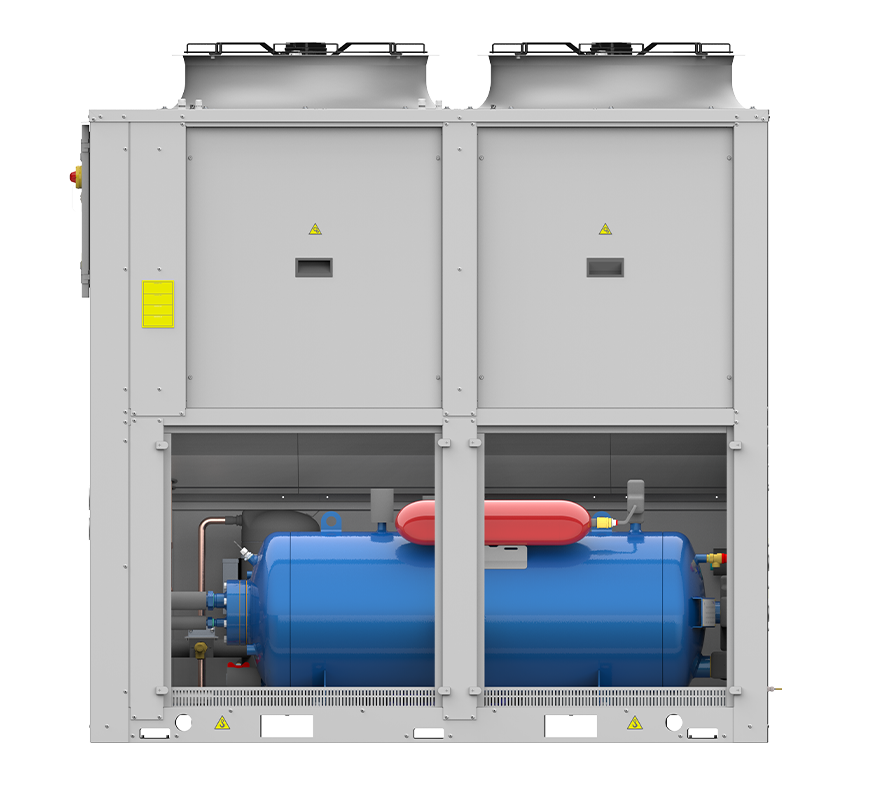

CONDENSER

Fin coil heat exchanger with copper tubes and corrugated aluminum fins. The technical solution with mini-tubes maximizes the surface affected by the air, allowing compact dimensions and a reduction of the refrigerant charge.

ELECTRICAL PANEL

Electrical panel made according to EN60204-1 with standard IP54 protection degree that allows outdoor installation.

STRUCTURE

Robust structure designed and built to ensure total resistance to atmospheric agents and corrosion.

AC-EC FANS

AC STANDARD axial fans

with IP54 protection degree with external rotor. The blades are made of corrosion-resistant PP technopolymer and are protected by a safety grid. The nozzle directly integrated into the impeller acts as a diffuser, increasing the fluid dynamic efficiency and reducing the noise level.

EC axial fans

(high efficiency, standard for LASER and LT versions), equipped with Brushless motor with electronic switching and integrated temperature control and continuous speed regulation from 10% to 100%.

CENTRIFUGAL PUMPS

High-pressure multistage horizontal centrifugal pumps, specifically designed for process cooling. Available head: P3 – 3barg; P4 – 4.5/5barg; P6 –6/6.5 barg. P5 INVERTER INOX pump with MGE motor equipped with permanent magnets and high-efficiency frequency converter

REFRIGERATION CIRCUIT

Equipped with hermetic scroll type compressors and optimized for operation with R134a refrigerant (mod.13-18) and R410A (mod.20-5A). These high-efficiency compressors are equipped with a 2-pole motor complete with overheating/overcurrent protection and an oil heating resistance. The EEV electronic expansion valve (standard from mod.20) is equipped with sensors placed on the refrigeration circuit and allows to optimize its operation in every thermal load condition, guaranteeing maximum efficiency at all times.

CONDENSER

Fin coil heat exchanger with copper tubes and corrugated aluminum fins. The technical solution with mini-tubes maximizes the surface affected by the air, allowing compact dimensions and a reduction of the refrigerant charge.

ELECTRICAL PANEL

Electrical panel made according to EN60204-1 with standard IP54 protection degree that allows outdoor installation.

STRUCTURE

Robust structure designed and built to ensure total resistance to atmospheric agents and corrosion.

AC-EC FANS

AC STANDARD axial fans

with IP54 protection degree with external rotor. The blades are made of corrosion-resistant PP technopolymer and are protected by a safety grid. The nozzle directly integrated into the impeller acts as a diffuser, increasing the fluid dynamic efficiency and reducing the noise level.

EC axial fans

(high efficiency, standard for LASER and LT versions), equipped with Brushless motor with electronic switching and integrated temperature control and continuous speed regulation from 10% to 100%

SEC-BLUE LIGHT CONTROL

The programmable microprocessor control SEC.blue Light SMP4600 allows to optimize the operation of the refrigeration and hydronic circuits and allows to easily connect the WRA ErP units to all BMS management systems.

- ON/OFF regulation of compressors based on set point temperature;

- Fan speed control;

- Measurement and display of process fluid inlet/outlet temperatures and ambient temperature;

- Control of preheat / antifreeze resistance (water side);

- Display of alarm history;

- Management of electronic expansion valve;

- Alarm management: HP; LP; antifreeze; tank level;

- Clean contact of general alarm;

- Remote ON/OFF digital input;

- LASER function of fine regulation of process temperature for single / double hydraulic circuit

(hysteresis ± 0.5K /± 0.1K); - TTL serial interface (RS485 option)

Versatile

The wide range of versions and the numerous configurations and accessories available make the WRA ErP suitable for all process cooling applications

Complete

Complete

WRA ErP not only ensures superior performance but also a set of extraordinary benefits designed to elevate your expectations and overcome industrial challenges with style and reliability.

Designed for process applications

WRA ErP is particularly suitable for the following sectors

WRA ErP is particularly suitable for the following sectors

Hydrogen / Renewable energy

Machine tools

Chemical / Pharmaceutical

Plastic / packaging

Compressed air treatment

Discover all our applications >

Documentation

Documentation

You might be interested in it too

You might be interested in it too

Contact us

Contact us

For any information do not hesitate to write to us, we are at your disposal!