WLA

Precision ErP

Air-cooled industrial liquid chiller, ErP2021 compliant, with scroll compressors, R410A refrigerant,

50-160 kW

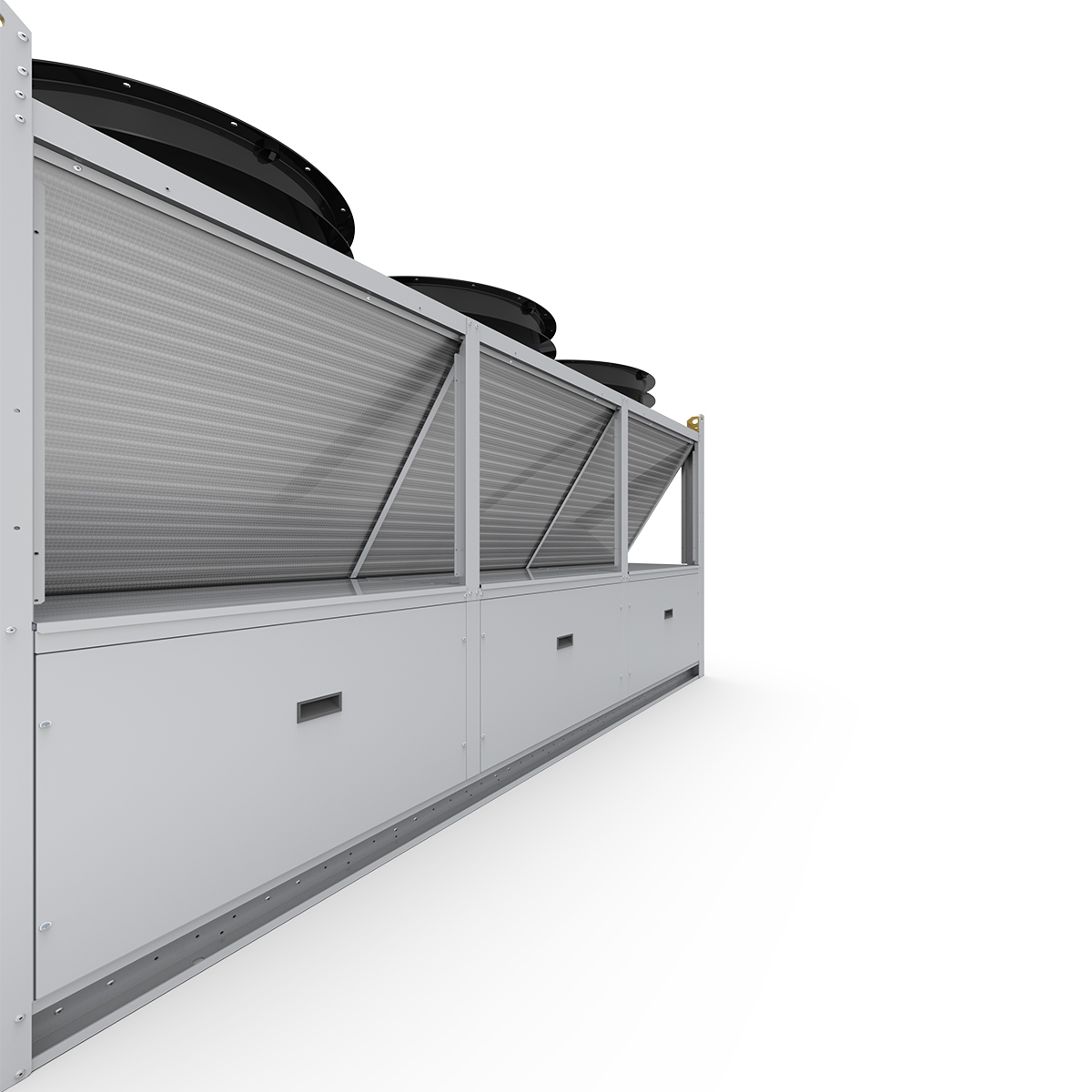

Condenser

Fin-tube heat exchanger with copper tubes and corrugated aluminum fins installed with a longitudinal “V” geometry, with an angle specially designed and selected to maximize the efficiency of the air-refrigerant gas heat exchange. The technical solution with mini-tubes maximizes the surface area affected by the air, allowing compact dimensions and a reduction in the refrigerant charge.

Electrical panel

The electrical panel is designed according to EN60204-1 and includes: the main switch with door lock, numbered electrical cables, automatic switches, and standard phase monitor. The standard IP44 protection level allows external installation (IP54 option). The active ventilation system is standard and includes a heating resistor and ventilation grilles.

Sec.blue Control

Programmable microprocessor control. IP54 UV-resistant graphical display with menus in 6 languages: Italian, English, German, French, Russian, Spanish.

Structure

Robust structure designed and made to ensure total resistance to atmospheric agents and corrosion. Base, uprights, and panels in galvanized carbon steel, assembled with stainless steel/galvanized metal hardware and painted with RAL 7035 polyester powder with a brushed finish.

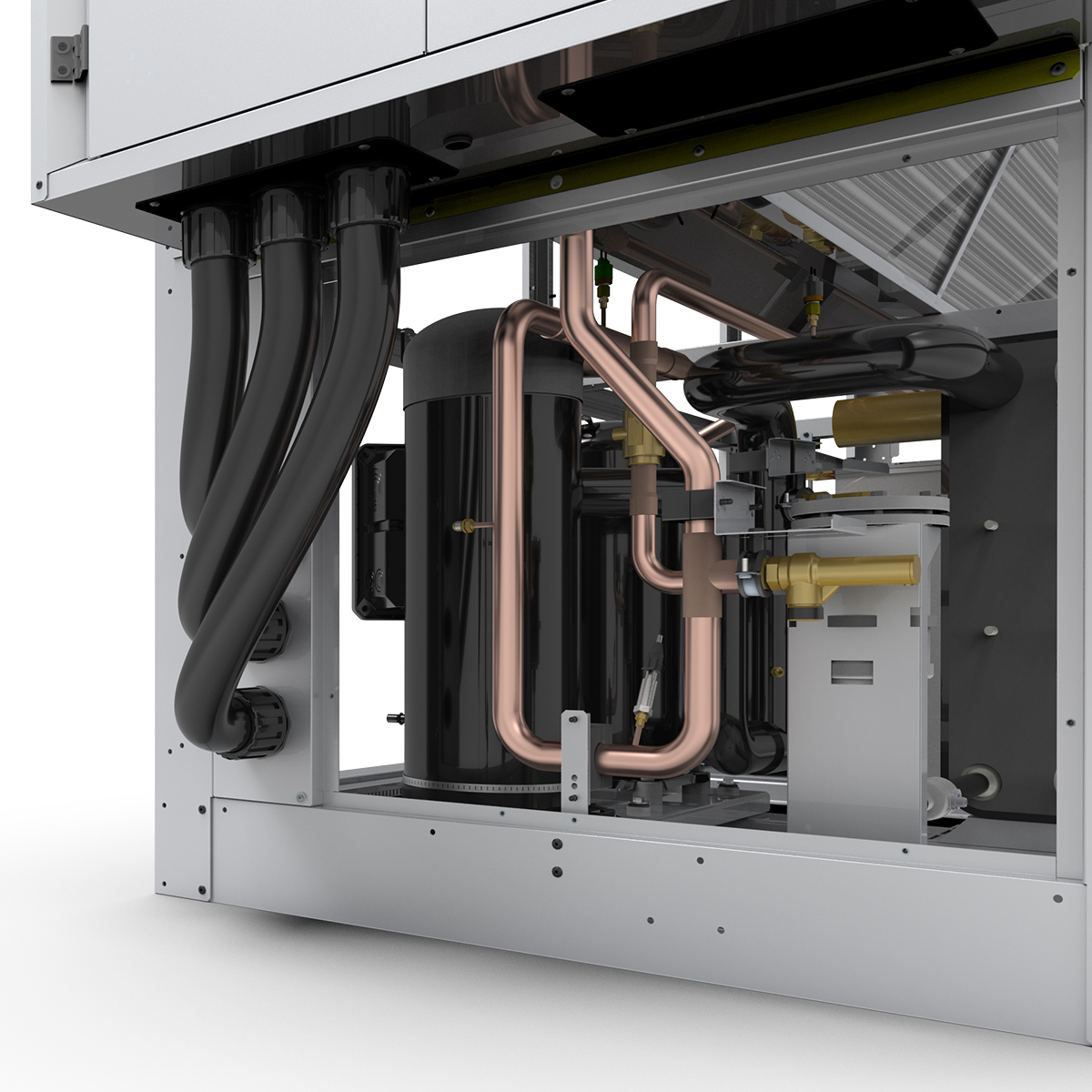

Refrigerant circuit

The refrigeration circuit is equipped with two hermetic scroll compressors installed in parallel and optimized for operation with the R410A refrigerant. These high-efficiency compressors are equipped with 2-pole motors complete with protection against overheating/overcurrent and an oil heating resistor. The standard electronic expansion valve EEV with sensors placed on the refrigeration circuit allows optimizing the operation of the refrigeration circuit under any thermal load condition, ensuring maximum efficiency at all times.

AC-EC Fans

Standard AC axial fans equipped with an asynchronous motor with IP54 external rotor protection and electronic speed control as standard. The blades are made of corrosion-resistant PP technopolymer and protected by a safety grille.

EC axial fans (standard for LASER and LT versions) with high efficiency, equipped with a brushless electronically commutated motor with integrated temperature control and continuous speed regulation from 10% to 100%.

Centrifugal Pumps

High-pressure horizontal multistage INOX centrifugal pumps, specifically head pressure designed for process cooling. Available head: P2 – 2barg P3 – 3barg; P5 – 4.5/5barg; double standby pump P3+P3. INOX P5 INVERTER pump with MGE motor equipped with permanent magnets and high-efficiency frequency converter.

The new WLA Precision range of industrial liquid chillers has been designed to guarantee the high standards of reliability required by production processes running 24/7 and perfectly meets the needs of applications that demand high standards of quality and reliability.

Thanks to the careful design and dedicated technological solutions such as evaporators and condensers with high exchange surface area, the electronic expansion valve as standard and the new high-efficiency axial fans, the WLA Precision ErP range is characterised by its high thermodynamic performance, which exceeds the minimum energy efficiency requirements imposed by the European ErP Ecodesign directive.

Strenghts

Strenghts

- Energy Efficiency: thermodynamic optimisation and increased exchange surfaces allow WLA precision ErP units to comply with the limits required by ErP2021 – SEPR HT (EU) 2016/2281 – SEPR MT (EU) 2015/1095.

- Extended operating limits: max outdoor air temperature +45°C; min -10°C (-20°C in LT version); max evaporator water outlet temperature up to +25°C; min 0°C (-10°C in BRINE version);

- Outdoor installations: the electrical panel made in accordance with EN 60204 and with IP44 protection rating (IP54 optional) allows outdoor installation;

- STANDARD version – Non ferrous: includes an AISI316 brazed plate evaporator protected from freezing by a differential pressure switch and an anti-freeze probe. The hydronic module is suitable for atmospheric hydraulic circuits and includes an AISI304 tank equipped with a level sensor and the circuitry composed of non-ferrous materials;

- Electronic Expansion Valve (EEV): optimises the operation of the refrigerant circuit under all thermal load conditions;

- Automatic hydraulic bypass valve: protects the pump and hydraulic circuit as a pressure limiting device;

- Phase monitor: provides protection against loss and electrical phase reversal;

- High efficiency brushless EC axial fans: standard for LASER and low ambient temperature LT versions.

Customised solutions for every need

Customised solutions for every need

- New PROCESS version for Pressurised Hydraulic Circuits: Includes a single-circuit direct expansion shell and tube evaporator with a carbon steel shell and copper tubes installed inside a carbon steel hydraulic tank. The design features of this technical solution allow the WLAprecision to operate reliably in heavy industrial applications and even with process fluids containing impurities.

- New LASER hysteresis version ±0.5K (mod. 5A- 7B): the LASERPACK control system integrates a hot gas bypass valve for regulating cooling capacity, brushless EC fans and a microprocessor control with an advanced PI algorithm to guarantee a standard hysteresis of ±0.5K under variable load conditions.

- New LT version for low ambient temperature -20°C: featuring dedicated control software, brushless EC fans and thermal insulation of the hydraulic circuit. BRINE centrifugal pumps feature an oversized motor suitable for high glycol concentrations.

- New BRINE version for glycol water outlet temperatures down to -10°C: includes hydraulic circuit insulation, and pumps with an oversized motor suitable for operation with high glycol concentrations.

- LOW GWP version with low environmental impact:

version available on request with environmentally friendly refrigerants (GWP < 750) F-Gas phasedown compliant.- R454B HFO refrigerant based on hydro-olefin. Class A2L slightly flammable. ODP = 0 and a low GWP value of 467.

- R32 refrigerante HFC. Classe A2L leggermente infiammabile. ODP = 0 ed un basso valore GWP di 675.

New electronic controller SEC.blue

New electronic controller SEC.blue

The SEC.blue programmable microprocessor control allows optimisation of the operation of the refrigeration and hydronic circuits and enables easy connection of the WLA precision units to all BMS management systems. The proprietary operating system is generally very flexible and can be extended with numerous additional parameters and functions on request.

Includes:

-

-

- IP54 UV-resistant graphic display with menus in 6 languages: Italian, English, German, French, Russian, Spanish;

- tft-LCD colour touch screen display 7 (option);

- General alarm dry contact;

- Remote ON/OFF digital input;

- No. 5 On-Off outputs (dry contacts) for alarms and pre-alarms settable via software;

- Remote control: graphic display / touch screen (option)

Sequencing function: allows up to 10 chillers, divided into 5 work zones, to be connected via a special line and managed as a single unit; - Emergency cooling function: in the event of failure of a chiller, an alternating chiller activation function is available to ensure continuity of operation;

- Dynamic set-point function: allows the fluid temperature to be adapted to the ambient temperature. It is also possible to change the chiller set-point via an integrated 4÷20mA analogue input;

- Integration with BMS supervision systems: SEC.blue includes as standard: Ethernet port, on RJ45 connector, for communication with HTTP, SNMP, ModBus TCP protocol and remote software update; RS485 port, for communication via ModBus RTU protocol; Monitoring via integrated web page, with alarm functions via email;

- LASER function: fine adjustment of process temperature (hysteresis ± 0.5K);

- Unloading function: keeps the chiller running even at high ambient temperatures;

- Demand limit function: allows the power consumption to be limited (ENERGY METER option required);

-

Designed for process applications

WLA Precision ErP is particularly suitable for the following sectors

WLA Precision ErP is particularly suitable for the following sectors

Hydrogen / Renewable energy

Machine tools

Plastic / packaging

Compressed air treatment

Discover all our applications >

Documentation

Documentation

You might also be interested

You might also be interested

Contact us

Contact us

For any information do not hesitate to write to us, we are at your disposal!