How to cool an electrical panel

How to cool an electrical panel

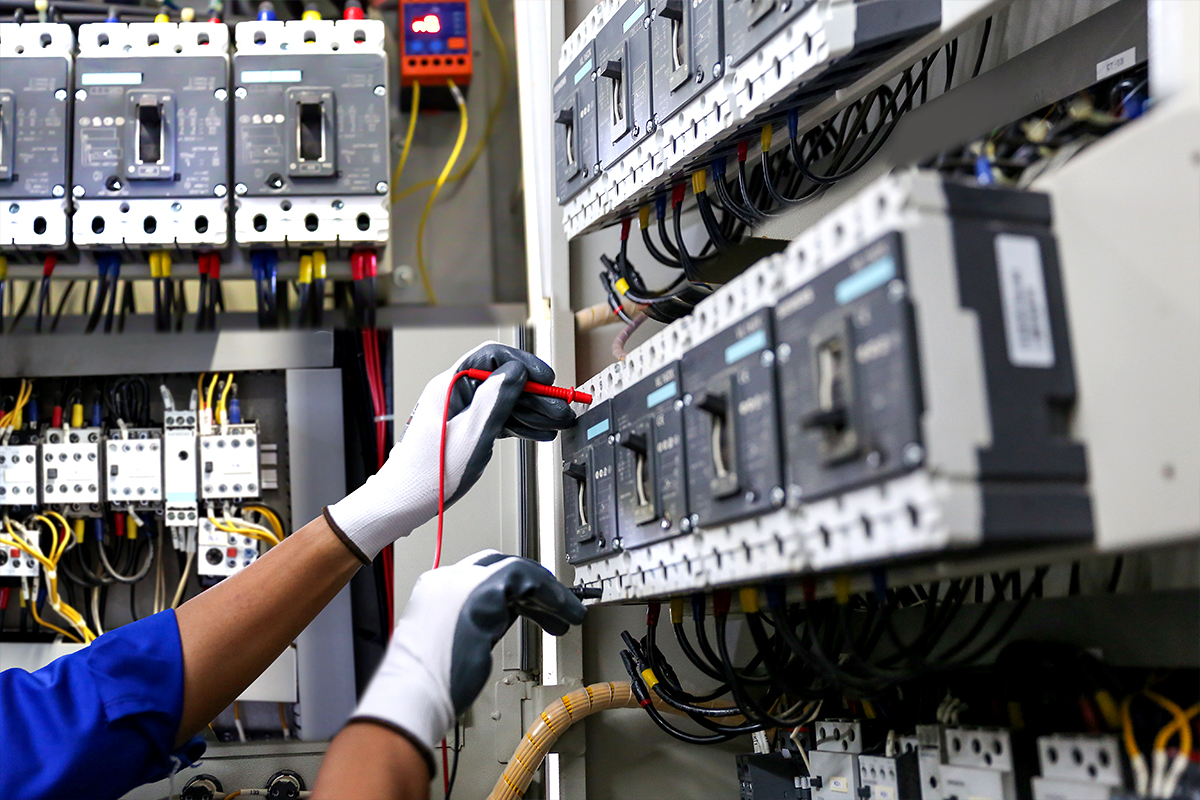

The electrical components within an automation panel have undergone a progressive process of miniaturisation and an increasing degree of complexity, increasing their presence and performance. These components must be protected from high temperatures and external agents, which increase their wear and tear and can cause them to become functionally downgraded to the point of final failure. Therefore it is essential to understand how to cool an electrical panel, so as to maintain its functionality and efficiency over time.

How is the heat transmitted?

Before understanding how to cool an electrical panel, let’s look at how heat propagation occurs.

Heat in the electrical cabinet is transmitted in three ways:

- thermal conduction: transmission of heat that occurs through a medium (solid, liquid or aeriform) without motion

- thermal convection: heat exchange associated with convective motion determined by a temperature difference

- radiation: transfer of energy between two bodies by means of electromagnetic waves

Thermal Management products maintain the temperature of the enclosure within the limits of the application and prevent the passage of dust, water, and external agents in the required manner.

How to choose a cabinet air conditioner

Now that we understand how heat is transmitted, let’s see what we can do to cool an electrical panel to ensure its flawless functionality.

The main factors in choosing the right solution are:

- Application, Indoor or Outdoor

- Air quality, presence of moisture, dust

- Reference temperatures, inside cabinet and maximum outside ambient

- Structural characteristics of the electrical panel (single-layer or multi-layer, material…)

- Thermal load of components

- Latitude (for outdoor application)

Air conditioners and water/air exchangers are recommended for:

- the outside air has a higher temperature value than the inside air

- the ambient air is extremely oily or soaked in dust and must not enter the control cabinet

Advantages of using industrial air conditioners for electrical enclosures

The advantages of an air conditioner are related to greater precision and ease of installation. They are ready for installation without having to set up any hydraulic circuit. They are usually the first choice for outdoor installations, where critical environmental conditions force the installation of this kind of product on cabinets.

When to choose a heat exchanger for cabinet cooling

Air/air heat exchangers are recommended if:

- the outside air has a lower temperature value than the inside air (usually approx. ΔT=10°C)

- not high cooling capacity is required

- little maintenance required

Air/Air heat exchangers are recommended if the ambient air is excessively oily or dusty, so that the cooler external air can be used directly to cool the switch cabinet.

Advantages of using industrial heat exchangers

The advantages of air/water heat exchangers are: no heat is released into the room and greater cooling capacity at the same size of an air conditioner. They can be the ideal choice, and allow high energy savings, if several air/water heat exchangers can be used in combination with a liquid chiller per application. However, it is necessary to have cold water available and to prepare the hydraulic circuit.

Flexibility in installation

Cosmotec, both for air conditioners and air/water heat exchangers offers solutions for wall or roof installation, for the first ones it is also possible to choose ranges for external, semi-recessed or external installation.

Ventilation solutions for electrical cabinets

For ventilation, Cosmotec offers both gfilter fans, to be placed on the wall of the cabinet, and roof mounted fans.

By your side in the choice

Cosmotec offers an easy and intuitive tool on its website, Cosmotec WebSelect, which can be used to dimension the actual heat load in the electrical panel and suggest the most suitable product for the application. By entering data relating to the above factors, the programme is therefore a valuable aid in determining the required cooling capacity and identifying the most suitable product.