Technology, innovation, and sustainability: our commitment is measured by actions

At cosmotec, we believe that innovation is not just a goal, but a continuous journey—driven by tangible investments, long-term vision, and attention to every detail of our work. That’s why we’ve chosen to invest in what truly matters: people’s development, production quality, process efficiency, and product engineering.

Our Innovation Center is a cornerstone of this journey. A technologically advanced space designed to prototype and test solutions that meet the challenges of today and tomorrow.

Every decision we make, from design to after-sales, is guided by the values that define us:

Sustainability

We design to reduce environmental impact throughout the entire lifecycle of our products.

Reliability

We ensure long-term operational continuity so that every system works when it’s needed most

Innovation

We bring new ideas to design, production, and services, always focused on continuous improvement.

Customer Focus

We listen, anticipate, and respond with scalable, tailored solutions.

Driven by our vision, we aim to be more than just equipment suppliers, we strive to be true value partners, growing together with our customers, suppliers, and collaborators.

The climatic chambers we have invested in, among the most advanced in Europe, were developed with this mindset: strategic tools not only to guarantee excellent products, but to establish ourselves as a benchmark in the industrial and IT cooling markets.

Greenovation HUB:

Technology that simulates reality, and beyond

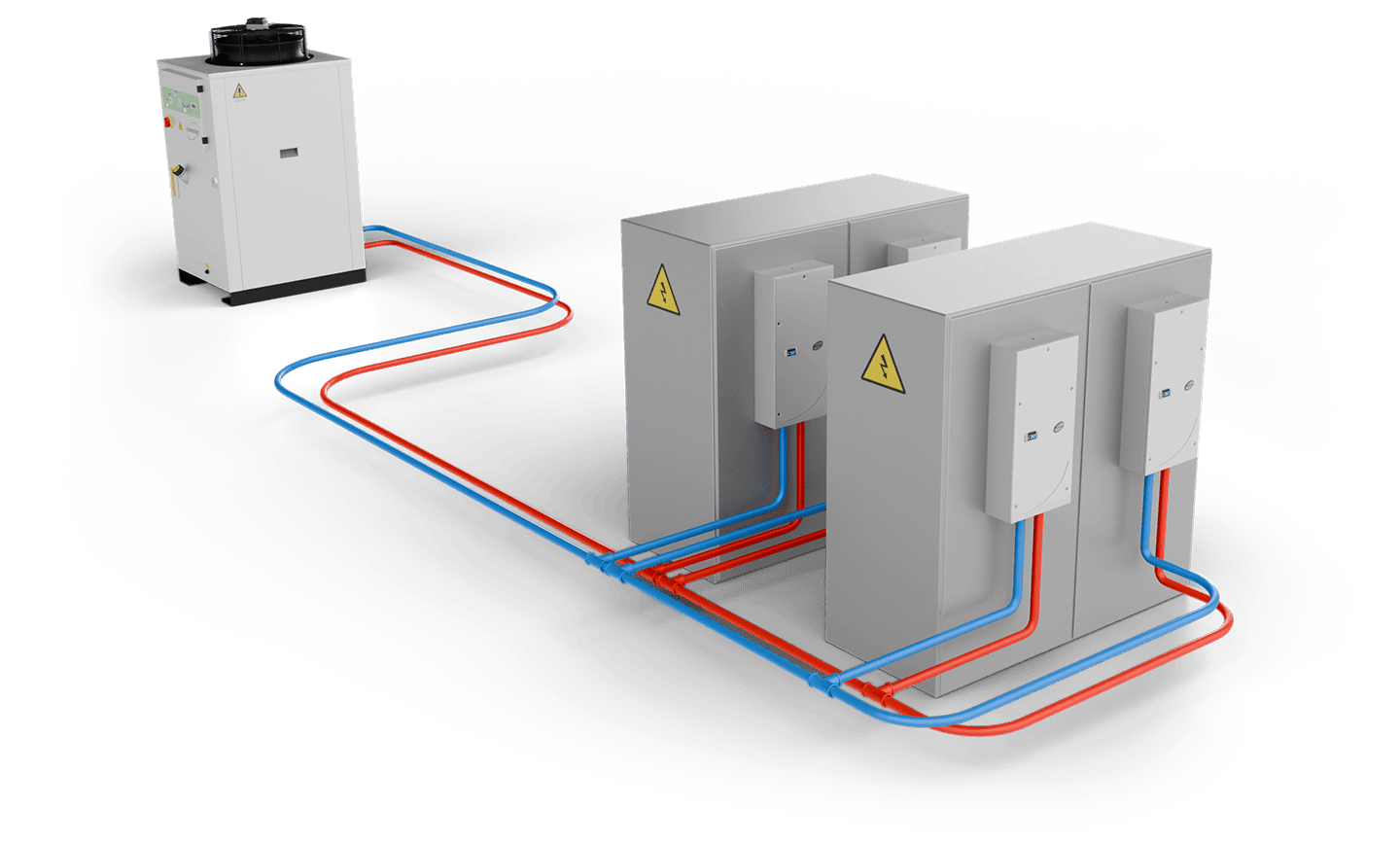

In markets where reliability, energy efficiency, and safety are non-negotiable, our climatic testing laboratory stands as one of the company’s strategic pillars. It’s more than just a test facility: it’s a true innovation center, where air conditioners, heat pumps, and HVAC systems up to 1850 kW are pushed to their limits under extreme conditions, with maximum precision and total safety.

At the heart of our lab are four independent climatic chambers, designed to replicate virtually any environmental scenario, from a freezing Arctic night to a scorching tropical afternoon. With a temperature range from -40°C to +55°C and relative humidity control up to 95%, every detail is engineered for accuracy. And we don’t stop at simulating outdoor conditions: each test is fully customized, featuring tailored climate profiles and the ability to operate multiple units in parallel.

Innovation and sustainability come together through the use of low-GWP refrigerants. These often pose safety challenges, as they belong to flammability classes A2L and A3. Equipped with dedicated systems, sensors, and emergency devices, our laboratories are among the few in Europe capable of safely managing next-generation refrigerants in compliance with ATEX and ISO/IEC standards—ready to meet the demands of new environmental regulations.

Beyond performance:

Comprehensive testing for outstanding products

In our laboratory, we don’t just test efficiency and performance, we validate the overall quality of every new product from every angle.

- Sound level testing → To assess acoustic impact under real operating conditions

- IP rating tests → To certify protection against the ingress of solids (dust) and liquids

- CE and UL compliance checks → To ensure electrical and mechanical conformity with European and North American standards

- Evaluation and optimization of design choices—such as sensor placement and control software configuration → To maximize product performance

Why choose us?

Because we’re ready for the future

✅ Operational flexibility → Simultaneous testing across multiple chambers and extensive customization

✅ Absolute precision → High-sensitivity instrumentation and automated control systems

✅ Reliability → Expert technical support and detailed reporting

✅ Future-ready vision → Always up to date with the latest regulations, refrigerants, and technologies

The ideal partner for thoose who build excellence

We collaborate with manufacturers, designers, and certification bodies at every stage—from prototype to pre-series, all the way to final certification. Our laboratory is more than just a checkpoint: it’s a true partner in the development of efficient, safe technologies ready for European and international markets.

Once the development phase is complete, the quality we bring to market is transparent and verifiable. Our testing facilities are available to customers for Final Acceptance Tests (FAT), ensuring that individual products and systems comply with a wide range of technical specifications.

To learn more, stay tuned for upcoming releases where we’ll explore all the details of our FAT offering.