Producing Cold Sustainably

cosmotec solutions for efficiency

The fight against climate change caused by the greenhouse effect is becoming increasingly necessary and urgent. To this end, legislative measures are already in place and will be further expanded, such as the Energy Efficiency Directive (2023/1791), focused on renewable energy sources, and the ErP or Ecodesign Directive (2009/125), which pertains to the design of sustainable products. The latter has significant implications in the fields of air conditioning and refrigeration and is based on several principles, including:

- Improving the durability, reusability, upgradability, and reparability of products

- Making products more energy and resource efficient

Efficiency and durability are interconnected characteristics. More efficient chillers and air conditioners experience less component wear, enhancing reliability and reducing maintenance needs, even under more demanding application conditions.

The strategies cosmotec has identified for optimal energy consumption include:

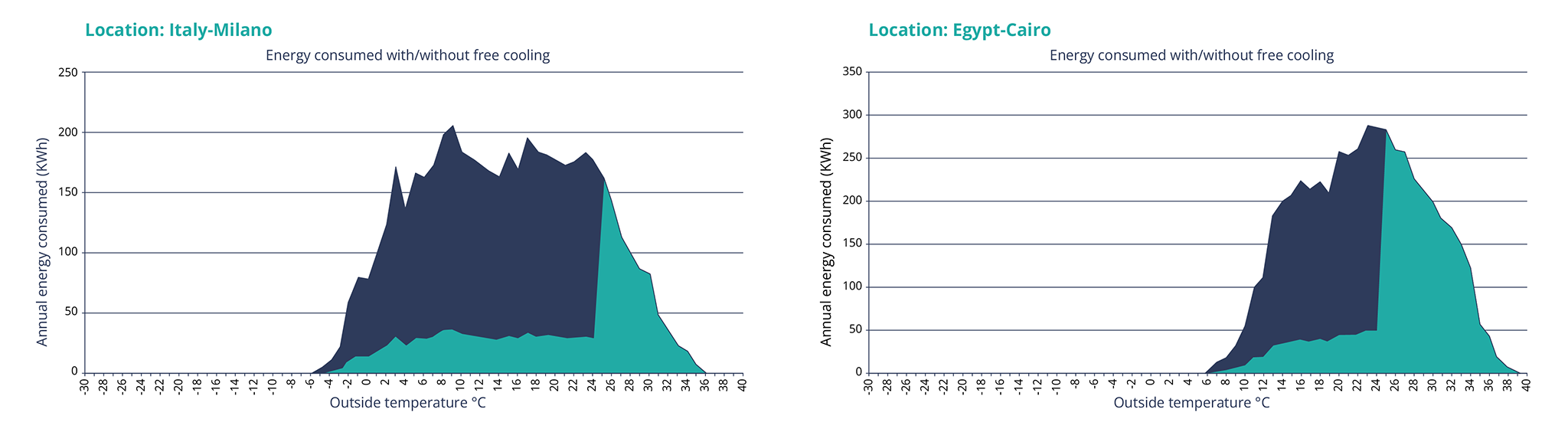

- Maximizing the use of free cooling whenever possible.

- Increasing the surface area of heat exchangers.

- Producing only the cooling required by the application, avoiding inefficient on-off cycles by using capacity modulation systems.

- Connecting our products to remote monitoring systems to ensure continuous operation control, prevent breakdowns and service interruptions, and maintain optimal efficiency throughout the product’s lifecycle.

- Addressing energy efficiency beyond individual products by managing complex cooling production and distribution systems in a coordinated manner.

What do cosmotec products offer?

Flexin CDI

Air conditioner with Inverter technology on the compressor, electronic expansion valve, and variable-speed EC fans. With continuous variation of cooling capacity based on actual thermal load: efficiency increases, temperature fluctuations inside the electrical panel are reduced, as well as compressor on-off cycles, benefiting the compressor's lifespan.

CDI20U123H90000 | CDI26U123H90000 | CDI40U123H90000 | |

EER (L35L35) | 3,6 | 3,2 | 3,7 |

EER (L35L50) | 2,5 | 2,1 | 2,5 |

Protherm, Compact Protherm, SlimIn

Even classic On/Off air conditioners offer excellent EER efficiency values, thanks to the use of high-performance compressors and fans, a large surface area condenser with micro-channels, and electronic controls with energy-saving functions (SEM and SEM2).

Esempi | CDE30A326180000 | CNE040022080000 | CVE20002618000 |

EER (L35L35) | 2,8 | 2,5 | 2,1 |

Predator

The air conditioners are equipped with a "natural cooling" system, free cooling, which uses properly filtered ambient air to cool the cabinet. The system does not waste energy and represents an excellent energy-saving solution, as it relies solely on the temperature difference between the internal and external environments. The evaporator fan is the only component in operation, while the compressor and condenser fan are turned off.

The proposed solutions enable a reduction of 30% to 80% in electrical consumption and CO₂ emissions,

depending on the operating conditions of the product.

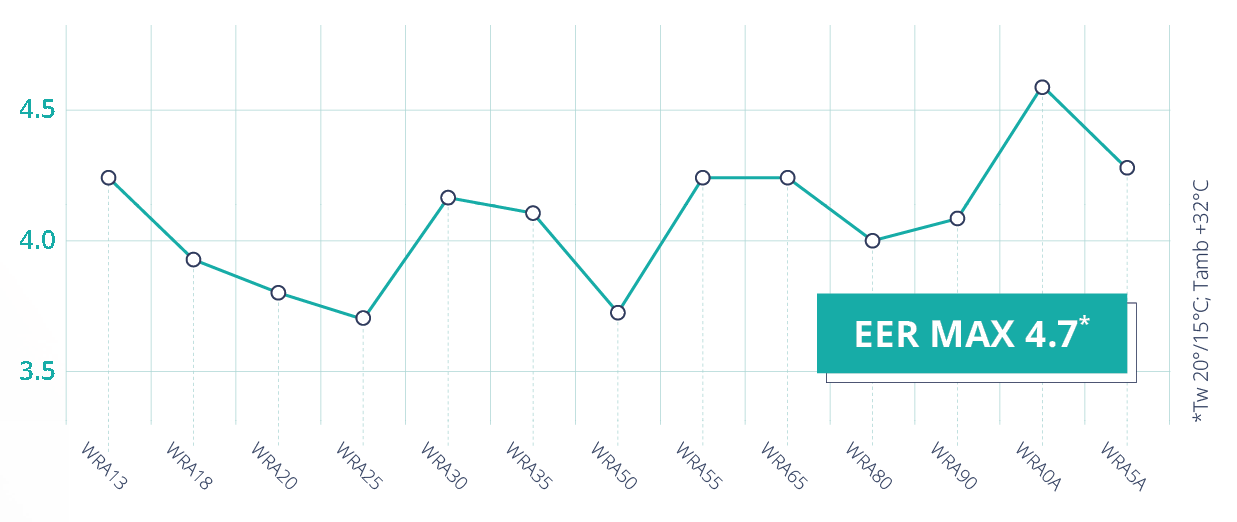

WLA Precision ErP, WRA ErP

The two new ranges of industrial liquid chillers stand out for their precise design and dedicated technological solutions, such as high-surface-area evaporators and condensers, standard electronic expansion valves, and new high-efficiency axial fans. This enables these chillers to achieve top-tier energy efficiency levels, in compliance with the limits set by the EcoDesign ErP2021 regulation - SEPR HT (EU) 2016/2281 - SEPR MT (EU) 2015/1095.

WSA ErP, WSI ErP

It is a range of high-efficiency, low environmental impact air-cooled liquid chillers with free cooling technology and cooling capacities from 280 to 1860 kW.

Designed for 24/7/365 process cooling applications, the WSA – WSI models feature one or two refrigerant circuits with stepless screw compressors (WSA) / inverter compressors (WSI) and high-surface-area evaporators. The WSA/WSI range achieves high energy efficiency levels (Class A or B), ensuring compliance with the limits set by the 2009/125/EC Ecodesign ErP 2021 Directive.

The WSA ErP chillers are available with integrated free cooling, which provides significant energy savings, especially in applications requiring high cooling fluid temperatures (e.g., plastics) and installations in cold or temperate climates.

By using external air to cool the fluid, the free cooling system can entirely replace the refrigeration circuit, allowing the compressors to be turned off.

The heat exchangers are sized to achieve a Total Free Cooling Temperature (TFT) that is 10°C lower than the setpoint temperature. The WSA – WSI units can be paired with FCB free cooling modules to maximize performance, further increasing the overall free cooling temperature TFT.

4.plant

It is our solution for monitoring, control, and optimization in industrial applications. This product enables precise analysis of unit performance and their systems to enhance overall efficiency and ensure long-term reliability.

Its architecture ensures interaction and collaboration among all devices within the cooling system:

- Maximizes free cooling utilization

- Manages and adjusts unit sequencing

- Controls fluid distribution, even with variable flow rates

- Dynamically and responsively monitors each component

- Verifies operational conditions of units through diagnostics

- Prevents oscillations and overproduction

cosmotec, with its unwavering commitment to energy efficiency, is a strategic partner in reducing energy consumption and CO₂ emissions, paving the way for a more sustainable future. Through technologies such as free cooling, high-efficiency heat exchangers, and advanced systems for optimizing integrated plants, we enhance operational performance and minimize interruptions and failures, ensuring greater long-term reliability.

Our solutions in industrial air conditioning and refrigeration provide customers with significant support in advancing projects toward a greener World.